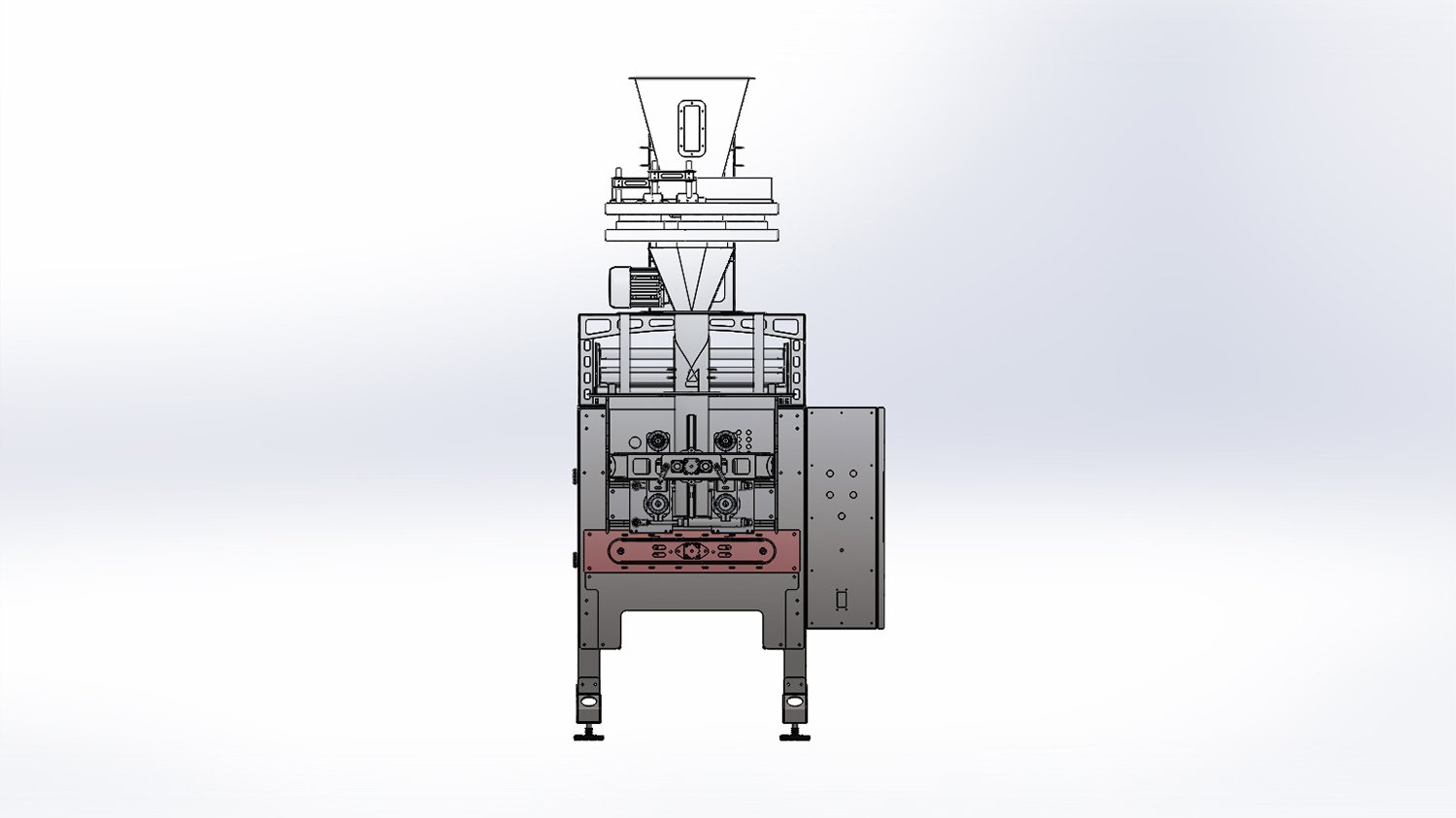

Machine Design

Client:

Concept Packaging Solutions (CPS)

Scope:

Design a new improved form, fill and seal machine to:

Reduce machine price

Reduce weight

Increase assembly time

Increase output

Increase production output

Design:

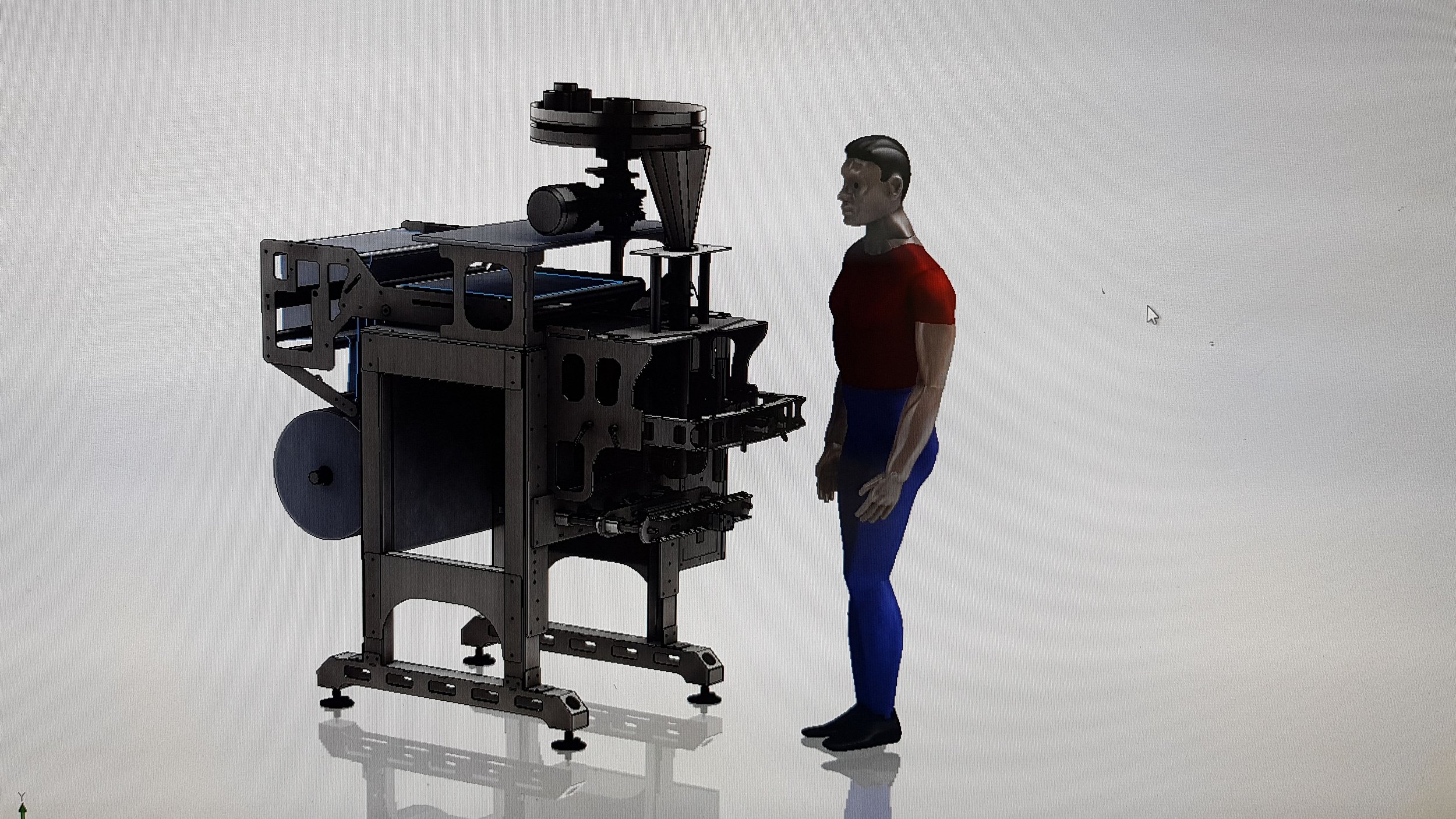

We took a new approach to the machine build to take into account the client’s internal and external resources and staff capabilities.

More time and effort was invested in the design process to reduce manufacturing time and cost.

Result:

The machine was manufactured using lower skilled staff and reduced manufacturing time from eight weeks to four weeks.

Machines cost was reduced while increasing output and reducing weight.

The number of machined components was reduced and replaced with laser cut, re-engineered designs.

Fabrication was almost eliminated and became more of an assembly process.

Machine became lighter and more compact making it more suitable for freight and export.